Monday, December 31, 2012

Ready for my Close up, Mr DeMille

Here they are, painted, weathered and ready for revenue service. 2 three compartment tank cars from Southern Car & Foundry.

The first of these kits are intended to be available in Cocoa Beach at the Prototype Rails meet in January.

These cars were actually fun to build. Somewhat of a departure for me. They should do very well. I'm pleased and proud to be able to have helped Jon Cagle with there models.

Look for more really neat tank cars from SC&F in the future.

And I really should mention that both cars are riding on Tahoe Model Works trucks. The best for the best.

Thursday, December 27, 2012

Step into the Wayback Machine, Mr Peabody.

I just mailed this car off to a client. It is a West Shore Line resin kit of a Lehigh Valley "wrong way door" boxcar.

It's worthy of note in that the kit is actually 20 years old. While the decals were a bit of a trial, the actual castings were in very good shape. The pattern work makes some of the offerings of today look a little sad.

I usually cringe when I open a box and find the old yellow "Alumilite" resin. But in this case the casting was very carefully done and as a result the car was a pleasant build.

I also got this car complete. It's the fuel tanker for an experiment the UP conducted with their turbines. They modified one locomotive to burn propane and as a result required this tankcar for the fuel.

The modeling project is well described in the UP Sig publication.

To date I've built 3 of these tankcars for clients. Not sure if I want to do another.

It's worthy of note in that the kit is actually 20 years old. While the decals were a bit of a trial, the actual castings were in very good shape. The pattern work makes some of the offerings of today look a little sad.

I usually cringe when I open a box and find the old yellow "Alumilite" resin. But in this case the casting was very carefully done and as a result the car was a pleasant build.

I also got this car complete. It's the fuel tanker for an experiment the UP conducted with their turbines. They modified one locomotive to burn propane and as a result required this tankcar for the fuel.

The modeling project is well described in the UP Sig publication.

To date I've built 3 of these tankcars for clients. Not sure if I want to do another.

Monday, December 24, 2012

Just in Time for the New Year

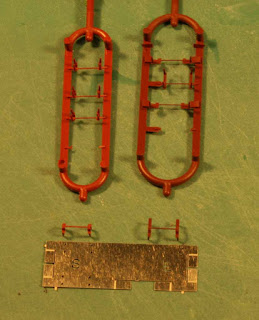

I've spent the last 2 days building these pilot models for my friend at Southern Car and Foundry.

They are 3 compartment tank cars on the Standard Tank Car Co. underframe.

The kits feature the usual high quality resin tank castings as well as underframe components we've come to expect from SC&F. One other new feature are hangers for AB brake components. The first set of tankcars from SC&F came with mounting brackets for K brakes only.

The models you see here are not complete yet as there was a little hiccup with casting the new parts, so I've taken the cars as far as I can and expect to see the errant bits by Friday. Fingers crossed.

SC&F hopes to have this kit ready for sale at the Prototype Modelers meet in Cocoa Beach this coming January

They are 3 compartment tank cars on the Standard Tank Car Co. underframe.

The kits feature the usual high quality resin tank castings as well as underframe components we've come to expect from SC&F. One other new feature are hangers for AB brake components. The first set of tankcars from SC&F came with mounting brackets for K brakes only.

The models you see here are not complete yet as there was a little hiccup with casting the new parts, so I've taken the cars as far as I can and expect to see the errant bits by Friday. Fingers crossed.

SC&F hopes to have this kit ready for sale at the Prototype Modelers meet in Cocoa Beach this coming January

Sunday, December 23, 2012

10,000

That's some kind of landmark, I believe.

10,000 views of this little blog of mine since it was launched. I'm a tad humbled that that many of you are interested enough in what I'm up to.

Thanks to all.

Wonder what the next year will bring?

10,000 views of this little blog of mine since it was launched. I'm a tad humbled that that many of you are interested enough in what I'm up to.

Thanks to all.

Wonder what the next year will bring?

Saturday, December 22, 2012

Roof, Windows and Chutes, Oh My!

The hobby shop called, the other 2 Tichy coal chutes came in. So I could now build the 4 discharge chutes and frames. The design is a crossblend of the Tichy chutes and the original design. A compromise I can live with.

The chutes still require counterweights and rope supports. There are walkways at each front corner and ladders for access to build. But for now it will rest in it's location.

I have to do a little landscaping around the rear before I can add the covered unloading section. All in good time.

It's stand back and admire time for now.

The chutes still require counterweights and rope supports. There are walkways at each front corner and ladders for access to build. But for now it will rest in it's location.

I have to do a little landscaping around the rear before I can add the covered unloading section. All in good time.

It's stand back and admire time for now.

Thursday, December 20, 2012

Less is More

I painted the coal dock with Floquil Aged Concrete. After letting that sit for a couple of days, I broke out the Pan Pastels and the Bragdon chalks and went for it.

And I wasn't happy at all. I sent the above photo to my buddy Trevor Marshall and we chatted about processes and desired looks. We also found one colour photo of a CN coal dock in service from the era I'm modeling. The vision I had in my minds eye was all wrong.

So it was back to the paint shop.

A full repaint with Aged Concrete. Then a overspray of regular Concrete. After letting that sit for a bit, I come in with a thin mix of Grimy Black and dusted in some tones and some exhaust stains.

Much better!

I'm going to leave the weathering alone until the coal chutes are installed and see what may be required.

Thanks Trevor.

The coal dock in it's natural habitat.

And I wasn't happy at all. I sent the above photo to my buddy Trevor Marshall and we chatted about processes and desired looks. We also found one colour photo of a CN coal dock in service from the era I'm modeling. The vision I had in my minds eye was all wrong.

So it was back to the paint shop.

A full repaint with Aged Concrete. Then a overspray of regular Concrete. After letting that sit for a bit, I come in with a thin mix of Grimy Black and dusted in some tones and some exhaust stains.

Much better!

I'm going to leave the weathering alone until the coal chutes are installed and see what may be required.

Thanks Trevor.

The coal dock in it's natural habitat.

Wednesday, December 19, 2012

Man, Those Guys do Nice Work!

I've just completed 3 of these kits from my buddy, Jon Cagle, the talent behind Southern Car & Foundry.

Working from patterns created by Gene Deimling, a truly stunning O scale freight car emerges.

Jon is using mixed media in his kits. Laser cutting, photo-etching and resin casting along with injection molded after market parts. By playing to the strengths of each medium really stunning models emerge.

I built 1 car for a client and the other 2 are being offered for sale.

If you're interested contact me through my website, http://www.elgincarshops.com/contact.php for pricing and shipping details.

Sunday, December 16, 2012

How do you Carve a Horse?

Take a block of wood and remove what doesn't look like a horse.

As annoying as that advice can be, it is the approach I used to get the roof done of the Aylmer coal dock.

I simply took a sheet of balsa wood, traced the oval shape of the roof onto it, cut it out and then tapered and shaped the slopes with the power sander and finalized with a little hand sanding.

I'm not worried about the grain since some form of roofing material will be going on over top. Most likely tissue paper secured with paint.

The "concrete" work on the silos and hoist house is now done. Time for painting. I've primed the model with cheap and cheerful grey primer from a spray bomb and once that's dry out comes the Floquil Aged Concrete.

Once the other 2 sets of Tichy coal chutes arrive at the hobby shop, I can proceed with the discharge chutes. The beginnings of one you can see in the foreground.

Then it'll be time to build the simple roof over the hopper unloading area, a simple enough lean to structure. Again all concrete.

But tomorrow it's back to work on freight cars. Have to pay some bills.

As annoying as that advice can be, it is the approach I used to get the roof done of the Aylmer coal dock.

I simply took a sheet of balsa wood, traced the oval shape of the roof onto it, cut it out and then tapered and shaped the slopes with the power sander and finalized with a little hand sanding.

I'm not worried about the grain since some form of roofing material will be going on over top. Most likely tissue paper secured with paint.

The "concrete" work on the silos and hoist house is now done. Time for painting. I've primed the model with cheap and cheerful grey primer from a spray bomb and once that's dry out comes the Floquil Aged Concrete.

Once the other 2 sets of Tichy coal chutes arrive at the hobby shop, I can proceed with the discharge chutes. The beginnings of one you can see in the foreground.

Then it'll be time to build the simple roof over the hopper unloading area, a simple enough lean to structure. Again all concrete.

But tomorrow it's back to work on freight cars. Have to pay some bills.

Saturday, December 15, 2012

The latest addition to my product line

I have now taken delivery of these drilling templates. They are designed to allow you to accurately layout the mounting holes for the Kadee bracket grabs on car sides and ends.

I've been using one for a few months now and I can't say enough about it, or about how much I love the Kadee bracket grabs. They are delicate looking but very robust, made from a very flexible plastic. The clever people at Kadee even created a mounting pin that requires no glue.

The items will be up on the Yarmouth Model Works website soon.

Friday, December 14, 2012

CPR car progress

What you see is the first trial assembly of the under frame for the CPR plywood car kit. Having done this the dimensions for the last of the etched parts can now be worked out and that artwork can be done.

The mold for the car body has just today been created. From there the exact dimensions for the running boards can be determined and that data sent off to the laser cutter.

I had hoped to have kits in time for the Cocoa Beach Prototype Rails event, but it's not looking likely. But certainly in time for Valentine's day. What better way to say "I love you" than with a resin kit?

Monday, December 10, 2012

Almost missing the obvious

Work progressed well this weekend on the Aylmer coaling plant.

The silos are attached to the leg structure, the sub-roof is in place and the trickiest bit, the angled connections between the silos and the legs was attached and filled with putty.

In my head, as work was progressing, I was going over how I was going to determine the actual shape of the the sloped bits that go from the leg frames to the silos. I knew they were going to be ellipses. I knew that the slope was 45 degrees. I know how to draw an ellipse once the lengths of the major and minor axis are known. It's a bit of a pain. Involves pins and string and virgin sacrifice, etc.

And then it dawned on me. Take the ABS drain pipe, cut it on the chop saw to the desired angle and the final shape is given.

Place this on the sheet styrene and trace.

Ta Da!

They fit the first time.

I'm very pleased with how this is shaping up.

The silos are attached to the leg structure, the sub-roof is in place and the trickiest bit, the angled connections between the silos and the legs was attached and filled with putty.

In my head, as work was progressing, I was going over how I was going to determine the actual shape of the the sloped bits that go from the leg frames to the silos. I knew they were going to be ellipses. I knew that the slope was 45 degrees. I know how to draw an ellipse once the lengths of the major and minor axis are known. It's a bit of a pain. Involves pins and string and virgin sacrifice, etc.

And then it dawned on me. Take the ABS drain pipe, cut it on the chop saw to the desired angle and the final shape is given.

Place this on the sheet styrene and trace.

Ta Da!

They fit the first time.

I'm very pleased with how this is shaping up.

Canada Post is starting to frost my weenie!

Fair warning! Right now I'm rather cranky.

So I went to the post office today to return to a fellow a mailer tube of drawings that he has kindly lent me for a future Yarmouth Model Works project. At the same time I purchased another mailer tube to sent a copy of the drawings to my buddy Aaron.

Now the tube was mailed to me from the US for a tad under $4.00.

Imagine my shock when the clerk informed me that postage for the tube was going to be $17.00, plus another $1.75 surcharge for it being a mailing tube.

I was also informed that the tube I had just purchased was over length, thus subject to a premium charge.

Given that the originals were not mine I felt I had to return them in the condition I received them in, but the other set were quickly folded and stuffed into an envelope and mailed for $4.00.

So let's review;

Canada Post sells over length mailing tubes that they really don't want to be bothered with and charge more than 4 times the US rate for handling said item. And they wonder why they continue to lose market share.

So I went to the post office today to return to a fellow a mailer tube of drawings that he has kindly lent me for a future Yarmouth Model Works project. At the same time I purchased another mailer tube to sent a copy of the drawings to my buddy Aaron.

Now the tube was mailed to me from the US for a tad under $4.00.

Imagine my shock when the clerk informed me that postage for the tube was going to be $17.00, plus another $1.75 surcharge for it being a mailing tube.

I was also informed that the tube I had just purchased was over length, thus subject to a premium charge.

Given that the originals were not mine I felt I had to return them in the condition I received them in, but the other set were quickly folded and stuffed into an envelope and mailed for $4.00.

So let's review;

Canada Post sells over length mailing tubes that they really don't want to be bothered with and charge more than 4 times the US rate for handling said item. And they wonder why they continue to lose market share.

Friday, December 7, 2012

The Aylmer Coal Plant

Ever since I went full time as a custom builder of resin kits, a number of people have asked me about keeping my interest level up and maintaining the energy to work on my own stuff. I don't mind telling you it's tricky balance. There are days where I just have to shove the cars aside and do stuff for the shear pleasure of the process. This structure fits the bill.

In the winter of 1943-44 CNR built, at the request of the Wabash, a new coaling plant in Aylmer, Ont. The idea was to reduce the number of refueling stops from 2 to 1 for the run across the province. Previously the Wabash would fuel at Glencoe and Nixon, where CN maintained large wooden coaling docks,as well as docks in Windsor and Fort Erie. They were all massive structures dating back to the Grand Trunk days.

I find it intriguing that the CNR would invest in major piece of infrastructure like this while there was a war raging Europe and the Pacific. And it's ironic that 7 years after it's construction it would be made redundant when the Wabash dieselized it's Ontario operations.

For my purposes, the structure still stands today, deemed to expensive to tear down. Which makes it simpler to model. It's a mere 20 minutes away should I need to look at something.

I finally got started on this imposing structure the other day. I started with the supporting framework, built up with styrene shapes following a drawing that was published years ago in an unknown publication that was sent to me by Steve Lucas. I'll be filling all the joints and sanding smooth once I'm sure I'm happy with the look of the unit. The silos are cut from 2.5" ABS drain pipe, which finishes out perfectly for the outside diameter. The roof will be a challenge, as I've yet to figure out how to execute it.

As it would only have been out of service for a few months in the era I'm modeling the coal chutes will be added to the final model.

This is going to look very sharp once it's done.

In the winter of 1943-44 CNR built, at the request of the Wabash, a new coaling plant in Aylmer, Ont. The idea was to reduce the number of refueling stops from 2 to 1 for the run across the province. Previously the Wabash would fuel at Glencoe and Nixon, where CN maintained large wooden coaling docks,as well as docks in Windsor and Fort Erie. They were all massive structures dating back to the Grand Trunk days.

I find it intriguing that the CNR would invest in major piece of infrastructure like this while there was a war raging Europe and the Pacific. And it's ironic that 7 years after it's construction it would be made redundant when the Wabash dieselized it's Ontario operations.

For my purposes, the structure still stands today, deemed to expensive to tear down. Which makes it simpler to model. It's a mere 20 minutes away should I need to look at something.

I finally got started on this imposing structure the other day. I started with the supporting framework, built up with styrene shapes following a drawing that was published years ago in an unknown publication that was sent to me by Steve Lucas. I'll be filling all the joints and sanding smooth once I'm sure I'm happy with the look of the unit. The silos are cut from 2.5" ABS drain pipe, which finishes out perfectly for the outside diameter. The roof will be a challenge, as I've yet to figure out how to execute it.

As it would only have been out of service for a few months in the era I'm modeling the coal chutes will be added to the final model.

This is going to look very sharp once it's done.

Wednesday, November 21, 2012

Alive! Alive! It's Alive!

It's a banner day here. After about 4 years of effort, with frequent interruptions for work and other annoying obligations, trains are finally able to run the full length of the layout. This afternoon after adding in the last of the IDCs (insulation displacement connectors. Suitcase connectors to some), I ran a Red Ball from one staging yard to the other and back.

The photo shows the train rolling into Jarvis, the most eastern station I'll be modeling.

So I'm doing my happy dance, wearing the short bus grin, patting my hands together, etc, etc. This is a major milestone in layout construction.

I can now make timings and develop the schedule. Scenery can now storm ahead. Look out bank account, Scenic Express is calling!

Heck I can even have friends over and we can run trains! Astonishing!

Speaking of friends. Here's some of the characters who have helped me get to where I am in such short time.

Left to right, Dylan Harris, Tim Warris, the late Rich Chrysler, Trevor Marshall and John Mellow. The goof with the throttle is me. Missing from the photo, Geoff Chrysler, John Spring, Brian Dicky and Thorsten Petschallies.

Then there's the fellows who provide the prototype data. Where would we be without them? Wes Dengate, Jim Rice, Ian Wilson, Helmut Osterman, Chet French, Rob Adams, and many, many more.

Thanks to all of you.

There's still lots to do, but it's a living thing now.

Think I'll go run a train.

Thursday, November 15, 2012

Better is easier, really!

Over time I've improved my modeling skills and techniques. Little tricks that I've gleaned from other modelers whose work I admire or detail parts that are truly superb. And as I was working on a trio of UP ACR boxcars today I couldn't help but realize that "improved" details actually are easier than compromise solutions.

Brake rods. For many years I would drill holes in brake levers, then bend little hooks in the wires to make a good mechanical connection and then add a touch of ACC to secure. Sometimes getting the rod that connected the live and dead lever right took a couple of tries. But now, by using cut up turnbuckle castings to replicate the clevis the job goes very quickly and looks so much better. It does mean making my own brake levers from 1x6 and 1x8 styrene, but even that is faster than trying to sand resin ones down to the right thickness. Better and faster.

Bracket grabs. Kadee offers their bracket grabs as part of their detail parts line. These are the best bracket grabs on the market, period. The plastic is very flexible, to the point that you'd have to really work at it to break them. And they mount very easily. Drill four #75 holes and press fit, you don't even really need glue. The grabs are designed with a tapered square pin that really holds well.

I even went so far the other day to cut one and turn the inboard bracket horizontal, as some end brackets were and was very pleased with the results

Sure beats farting around with brittle styrene offerings.

So the object lesson is push your boundaries, you may find that it's a lot easier to get the results you didn't think you could.

Brake rods. For many years I would drill holes in brake levers, then bend little hooks in the wires to make a good mechanical connection and then add a touch of ACC to secure. Sometimes getting the rod that connected the live and dead lever right took a couple of tries. But now, by using cut up turnbuckle castings to replicate the clevis the job goes very quickly and looks so much better. It does mean making my own brake levers from 1x6 and 1x8 styrene, but even that is faster than trying to sand resin ones down to the right thickness. Better and faster.

Bracket grabs. Kadee offers their bracket grabs as part of their detail parts line. These are the best bracket grabs on the market, period. The plastic is very flexible, to the point that you'd have to really work at it to break them. And they mount very easily. Drill four #75 holes and press fit, you don't even really need glue. The grabs are designed with a tapered square pin that really holds well.

I even went so far the other day to cut one and turn the inboard bracket horizontal, as some end brackets were and was very pleased with the results

Sure beats farting around with brittle styrene offerings.

So the object lesson is push your boundaries, you may find that it's a lot easier to get the results you didn't think you could.

Tuesday, November 13, 2012

Making things make sense

So it all started with this first photo. A pair of Wabash F-7s, a Wabash caboose and a Wabash SW-8 about to cross or having just crossed Talbot street in St Thomas. When I first saw this photo I had assumed that the photo showed a set of units returning from being serviced in either the PM/C&O shops or the NYC shops which was just south of this location. As the Wabash had no major servicing facilities in Ontario, they did contract with both of the other railroads to provide locomotive service.

But my suspicious nature had me wondering if this really the story behind this photo.

Then on Sunday past I purchased this next photo from Helmut Ostermann, which shows a Wabash train on the London & Port Stanley right of way. A right of way that is perpendicular to the Wabash trackage. (See the map below.) Helmut told me to contact Wes Dengate, a well known Wabash historian for the full story. Which I did. And it now all makes sense.

Both images are from the summer of 1952. That summer there was a strike by the car ferry captains on the Detroit River, which would have prevented the Wabash from moving any traffic to Buffalo. So the Wabash struck a deal with the NYC, C&O and L&PS to allow them to continue moving traffic across Ontario.

The Wabash was given permission to use the NYC tunnel in Detroit and they ran on the NYC trackage as far as St Thomas. Red Balls would pull into the St Thomas NYC yard, then a SW-8 would couple onto the rear to keep slack out of the train as well as assist in breaking the train to keep the level crossings clear. The train would back around the curve onto the L&PS/C&O trackage, then proceed north, across the NYC and across the Wabash main out over the L&PS trestle over the Kettle Creek. Then again back around the west leg of the wye, and finally get onto the Cayuga sub and resume normal activity.

You can follow all this on the map. You may wonder why they didn't use the curve on the north side of the NYC main. That track radius was too tight for mainline equipment.

The further explanation of the first photo, why is there no freight cars, is clear now. St Thomas was a crew change point. Under normal circumstances west bound Red Balls would leave the consists standing to the east of the CPR interchange and run in to the yard with motive power and cabooses only, perform the crew swap, and then return to the train and proceed west.

It is clear to me now that something like that is going on in the first photo we see.

This whole maneuver must of played havoc with the timetables and frayed not a few nerves. This went on for most of the summer of 1952. But it is neat to note that 4 competing railroads worked together to solve a problem.

Sometimes, It's the Little Things

Every now and then I get requests for smaller jobs, like a paint job and a custom decaling request. And usually they're straight forward. But they can lull one into a false sense of security.

This car was sent to me, to be painted PRR Tuscan and lettered as you see. The origin of this model is a mystery. The box has no label, and there's no "Made in..." cast onto the car. But it's a nice little model that was factory painted and lettered.

The first step was to attempt to remove the factory paint. To my amazement a bath in Scalecoat Paint and decal Remover didn't touch the factory finish at all. "Impressive!", I thought.

So painted over the factory finish with Scalecoat PRR Tuscan and was pleased to note that the factory lettering seemed to disappear. I left that to cure for a few days, so I could mask off the body and paint the underbody and end platforms black.

Once I could no longer smell solvent from the body colour, out came the Tamiya masking tape, on went the black. As I pulled the tape off, most of the Tuscan along with the factory paint and lettering also came off!

AAARRRGGGHHH!

Solvents wouldn't touch this paint but it pulls off with tape!?

Mind blowing!

I let the black cure, taped it off and reapplied the Tuscan. This time everything stayed in place.

The model goes back to it's owner today. I hope he's pleased.

Wednesday, November 7, 2012

A New Weapon in the Arsenal

I just finished weathering these 2 cars for a client.

Along with the usual air brush oversprays, I used a relatively new product for a few of the streaking effects.

Pan Pastels weathering colors. Similar to weathering chalks, but far less messy to use. And easier to control.

I had seen a clinic on this material a couple of years ago in Naperville and at the time discussions were underway with the manufacturer to release a set of "weathering" colors. I picked this set up a little while ago and fiddled with them some. I'm very pleased with the results.

This medium will now become a permanent part of my repertoire of weathering materials.

Along with the usual air brush oversprays, I used a relatively new product for a few of the streaking effects.

Pan Pastels weathering colors. Similar to weathering chalks, but far less messy to use. And easier to control.

I had seen a clinic on this material a couple of years ago in Naperville and at the time discussions were underway with the manufacturer to release a set of "weathering" colors. I picked this set up a little while ago and fiddled with them some. I'm very pleased with the results.

This medium will now become a permanent part of my repertoire of weathering materials.

Monday, November 5, 2012

Operations on the Hagersville Sub

This Saturday past, the CN Hagersville Sub layout of my late friend, Rich Chrysler, was open to the public for the annual H.O.M.E.S club layout tour.

It was one of his hopes that we, his friends, would be able to get more work done on the layout and get it running for this layout tour. I happy to say that we succeeded. Led by his son, Geoff, a number of work sessions occurred following Rich's death which assured that the layout was more than ready for the big day.

Geoff in particular, worked like a man possessed to honour his father's wishes. The 2 linked scenes of Simcoe and Simcoe South went from plywood to nearly complete in a very short space of time.

On Saturday we had over 200 people come through to view the layout and in their own way pay tribute to his passing. It's still hard to believe that Rich touched so many lives during his short stay with us.

The future of the layout remains unsure, but Geoff very much wants to keep it going. There's still much to do and untold hours of operations to come. And first we have to track down all the little gremlins that popped out as soon as visitors appeared.

Everybody stop looking at the layout!

Geoff has posted some nice video of the layout on YouTube. Have a look.

http://www.youtube.com/watch?v=giAlsus-SPQ

http://www.youtube.com/watch?v=7iVU598b1EE

http://www.youtube.com/watch?v=YdL1J1Vr_58

It was one of his hopes that we, his friends, would be able to get more work done on the layout and get it running for this layout tour. I happy to say that we succeeded. Led by his son, Geoff, a number of work sessions occurred following Rich's death which assured that the layout was more than ready for the big day.

Geoff in particular, worked like a man possessed to honour his father's wishes. The 2 linked scenes of Simcoe and Simcoe South went from plywood to nearly complete in a very short space of time.

On Saturday we had over 200 people come through to view the layout and in their own way pay tribute to his passing. It's still hard to believe that Rich touched so many lives during his short stay with us.

The future of the layout remains unsure, but Geoff very much wants to keep it going. There's still much to do and untold hours of operations to come. And first we have to track down all the little gremlins that popped out as soon as visitors appeared.

Everybody stop looking at the layout!

Geoff has posted some nice video of the layout on YouTube. Have a look.

http://www.youtube.com/watch?v=giAlsus-SPQ

http://www.youtube.com/watch?v=7iVU598b1EE

http://www.youtube.com/watch?v=YdL1J1Vr_58

Tuesday, October 23, 2012

Running on the Maumee Route

In advance of last weeks Prototype Modelers Conference in Naperville, I had the opportunity to operate on Bill Darnaby's layout, The Maumee Route.

I've been keen to run on this layout from the first time I saw it a few years ago and it certainly did not disappoint.

Bill has said that the whole point of the layout was to allow modelers to run realistic Timetable and Train Order operations. Stations are placed far enough apart to create a sense of distance and the layout design assures that operators can't peak down the line to see if the line is clear. Combine that with Bill's extensive modeling talents and the layout is true masterpiece.

One has to read and understand the schedule, the train registers and any train orders issued to be able to proceed on the line and avoid collisions. As you roll by the stations on the layout you have to check the train order boards for orders.

I can tell you that as a neophyte on the layout there was, at times, a high level of internal stress as I struggled to remember all the little details I was required to concern myself with.

I'm happy to report that I was not responsible for any impromptu meetings of equipment, but I did neglect to sign the train register for one arrival towards the end of the session. (Sorry Bill).

While I have much more to learn about TT&TO operations, I now feel that I've got a better handle on the whole process and am getting closer to being able to implement TT&TO on my Wabash layout once it's ready to roll.

I hope to be invited back in the future to repeat the experience and will put the lessons learned to good use with the Cayuga Sub of the Wabash in due course.

Monday, October 22, 2012

The Freight Car Summit

I've been spending the morning getting sorted out and reorganized following my return from almost a week in Naperville IL where I was participating in the Railroad Prototype Modelers Conference.

An annual event , now hosted by Joe D'Elia, where prototype modelers from all over the US and Canada get together to discuss trains and how best to model them.

Wandering the halls are such well known modelers like Andy Sperandeo, Tony Koester, Tony Thompson, Richard Hendrickson, etc. Over the course of 3 days 42 separate speakers give clinics on a huge variety of topics, from Freight car trucks to passenger operations on the ATSF.

Frankly I can't say enough about this event. I have attended at least 8 times now, when the personal schedule permits, and have always come away with new knowledge and new modeling friends. It's also an opportunity to renew relationships with people from the other side of the continent. I know that some are scared away by the notion of spending days with a "bunch o rivet counters", but it's much more than that. Just to visit the display room is a treat onto itself. Spectacular modeling and a venue to exchange ideas and techniques.

On the Saturday, after I gave my clinic at 9:00 am, I dashed off to the sales room to man my table. I was selling Wabash stock car kits and etched ladder stiles and eyebolts. Within 1/2 an hour I was sold out of 2 of the 4 ladder styles I had brought. The rest of the ladders were gone by 1:00. Good thing I had ordered more etchings before I had left home. Looks like I got this one right!

The photo shows the table in the afternoon with Al Ferguson anchoring the corner with his decals and my good friend Bill Welch perusing photos on the other side. In the end I came home with only 3 kits from my line and a few of the SC&F tankcar kits I was selling for Jon Cagle.

On that note, I will have a few SC&F tankcar kits available for sale now. Built or unbuilt. As you wish.

An annual event , now hosted by Joe D'Elia, where prototype modelers from all over the US and Canada get together to discuss trains and how best to model them.

Wandering the halls are such well known modelers like Andy Sperandeo, Tony Koester, Tony Thompson, Richard Hendrickson, etc. Over the course of 3 days 42 separate speakers give clinics on a huge variety of topics, from Freight car trucks to passenger operations on the ATSF.

Frankly I can't say enough about this event. I have attended at least 8 times now, when the personal schedule permits, and have always come away with new knowledge and new modeling friends. It's also an opportunity to renew relationships with people from the other side of the continent. I know that some are scared away by the notion of spending days with a "bunch o rivet counters", but it's much more than that. Just to visit the display room is a treat onto itself. Spectacular modeling and a venue to exchange ideas and techniques.

On the Saturday, after I gave my clinic at 9:00 am, I dashed off to the sales room to man my table. I was selling Wabash stock car kits and etched ladder stiles and eyebolts. Within 1/2 an hour I was sold out of 2 of the 4 ladder styles I had brought. The rest of the ladders were gone by 1:00. Good thing I had ordered more etchings before I had left home. Looks like I got this one right!

The photo shows the table in the afternoon with Al Ferguson anchoring the corner with his decals and my good friend Bill Welch perusing photos on the other side. In the end I came home with only 3 kits from my line and a few of the SC&F tankcar kits I was selling for Jon Cagle.

On that note, I will have a few SC&F tankcar kits available for sale now. Built or unbuilt. As you wish.

Sunday, October 7, 2012

Next!

What you see will be Yarmouth Model Works next kit.

The CPR 223950 plywood sheathed car. This was a wartime build, using 5/8" plywood in lieu of steel plate for side sheathing. The use of plywood saved over 2000 lbs in weight and retained the full interior width.

The panels were afixed through steel straps overlaying the side panels using a distinctive double row of rivets.

Aaron Gjermundson has faithfully recreated the look of this unique car in creating the patterns we'll be using.

The kit will feature the same kinds of details seen in our Wabash stock car. Laser cut running boards, Tahoe Model Works truck frames, Black Cat decals, photo-etched ladder stiles, stirrups and other details.

If all goes well, this kit may be ready to ship before Christmas.

Check in to the website to see when this kit will be ready.

Friday, October 5, 2012

With a little help from my friend

My good friend Trevor Marshall spent the day with me and we wired and tested the towns of Courtland and Delhi. A very successful procedure and a nice change from building cars for day.

That's me running #124 through the track in Delhi. And Trevor branding the ties to suggest fishplates. :-)

It was hoped that today was going to be a banner day. Where we ran a Red Ball from one end to other. Sadly not to be.

In the excitement and anticipation I had forgotten that I have yet to wire the town of Jarvis. Sigh.

That will take me about a day and then we can roll trains.

Saturday, September 29, 2012

More New Stuff

I've discussed car ladders a couple of times on this blog. If you've been paying attention, you'll have noticed that I've been rumbling about doing something.

Well here it is. I'm now retailing etched ladder stiles in 4 styles.

Ladder Types;

14" 8 rung

16" 7 rung

16" 8 rung

18" 7 rung

I've always been frustrated with plastic car ladders. Flash to clean

off. Rungs that break when desprueing. Oversize rung diameters.

These ladder stiles are photo-etched brass and are available in 4 rung spacings. The stiles are pierced for 0.012" wire grabs if you use Tichy grabs you may have to ream out the holes a tad, since Tichy uses 0.0125" wire for their grabs.

The parts are easy to use. Cut the stiles from the fret and either using a tool like "Etch-Mate" or a steel ruler and a single edge razor blade, fold the stiles into an angle. Use either commercial straight grabs or form your own for the rungs. Now you can easily use 0.010" or 0.008" wire if you desire for a more scale appearance. Cut the legs of the grab very short and insert in the holes. Secure with CA or solder. Small tabs of styrene inside the angle can be used to create standoffs.

I'm also releasing etched eyebolts in 2 styles.

The commercial bent wire eyebolts have always been oversize. By photoetching we can reduce the size to a far more prototype appearance.

We offer 2 frets of eyebolts with a mix of sizes to serve all your needs.

The photos show the parts with a piece of 0.010" wire so you can get a real sense of small these items are. But since they're phosphor bronze they are robust.

They come either with or without simulated collars

All of these items will be listed on the Yarmouth Model Works website within the week.

All items are $3.00 ea, plus mailing costs. Which will vary according to amount ordered.

I will have these items on display in Naperville for the Railroad Prototype Modelers meet, Oct 18-20. I will be presenting a clinc that week as well as selling in the sales room on the Saturday. Maybe we'll see you there.

Well here it is. I'm now retailing etched ladder stiles in 4 styles.

Ladder Types;

14" 8 rung

16" 7 rung

16" 8 rung

18" 7 rung

These ladder stiles are photo-etched brass and are available in 4 rung spacings. The stiles are pierced for 0.012" wire grabs if you use Tichy grabs you may have to ream out the holes a tad, since Tichy uses 0.0125" wire for their grabs.

The parts are easy to use. Cut the stiles from the fret and either using a tool like "Etch-Mate" or a steel ruler and a single edge razor blade, fold the stiles into an angle. Use either commercial straight grabs or form your own for the rungs. Now you can easily use 0.010" or 0.008" wire if you desire for a more scale appearance. Cut the legs of the grab very short and insert in the holes. Secure with CA or solder. Small tabs of styrene inside the angle can be used to create standoffs.

I'm also releasing etched eyebolts in 2 styles.

The commercial bent wire eyebolts have always been oversize. By photoetching we can reduce the size to a far more prototype appearance.

We offer 2 frets of eyebolts with a mix of sizes to serve all your needs.

The photos show the parts with a piece of 0.010" wire so you can get a real sense of small these items are. But since they're phosphor bronze they are robust.

They come either with or without simulated collars

All of these items will be listed on the Yarmouth Model Works website within the week.

All items are $3.00 ea, plus mailing costs. Which will vary according to amount ordered.

I will have these items on display in Naperville for the Railroad Prototype Modelers meet, Oct 18-20. I will be presenting a clinc that week as well as selling in the sales room on the Saturday. Maybe we'll see you there.

Maybe it's an illness

I actually enjoy building stock cars.

Here's 3 more Sunshine stock car kits. ATSF SK-R, SK-T and SK-U. Really nice pattern work from Charlie Slater. Through these cars you can see the progression of the end design as the railroad worked at making it easier and safer for the crews to access the end doors to inspect the loads.

I had a nice time building these cars and they all have my usual level of detail upgrades. Full underbody rigging and plumbing including brake rod clevis.

These cars are going on Ebay this afternoon and if they don't sell I'll bring them to Naperville and perhaps sell them there

Subscribe to:

Posts (Atom)